Product Description

Surface treatment for CNC Machining part:

| 1 | Zinc/nickel/chrome plating |

| 2 | hot galvanized |

| 3 | painting |

| 4 | powder coating |

| 5 | Anodize Oxidation, or with colors: like silver, blue, red, etc. |

| 6 | plating, silver-plated, Gold-plated, etc |

| 7 | polishing |

| 8 | electrolytic polishing |

| 9 | sank without electricity nickel |

| etc | etc. |

HangZhou CHINAMFG Machinery Co., Ltd. is located in HangZhou, HangZhou. Based on the advantages of specialized talents, it has formed 4 professional project sections with excellent technical equipment, sound quality assurance system and standardized production environment: mechanical processing, sheet metal stamping production, Mold manufacturing, high-speed rice transplanter, with the high recognition of the majority of mature customers, cast the “Xin Rifeng” brand in the industry’s CHINAMFG position, and strive to build an intelligent manufacturing service system.

It is people-oriented, Difeng people focus on the production of high-quality rice transplanter planting department with high quality and advanced technology, all kinds of mold design, R&D and manufacturing required for sheet metal stamping; at the same time, develop continuous die and welding.

We always adhere to the customer’s position to solve the problem, the product to achieve process optimization, reduce costs, and continue to reduce materials for the purpose, so for the domestic major Asian high-speed main engine factory and high-speed rice transplanter market, some products are sold to Pakistan, Vietnam, Countries and regions such as India. It has successively become an excellent supplier of domestic famous enterprises such as Japanese Yanmar, Japan Kubota, Nideko Electric, Hailiwei and ZheJiang Xihu (West Lake) Dis.. The company has successively obtained the “HangZhou Small and Medium-sized Specialized Special New Product (Technology) Certificate” and “ISO9001 Quality Certification” and successfully registered the “Xin Rifeng” trademark.

Workshop equipment

Certifications

Packaging & Shipping

FAQ

Q1: Are you a factory or a trading company?

A1: We are a professional manufacturer of CNC parts for over 14 years.

Q2: How can I get quotation?

A2: Please help to send drawing (2D and 3D drawing) to us, so we can know the raw material, size and surface treatment, tolerance and other details of the product. And also inform us the quantity you need.

Q3: What kind of material you can process?

A3: Normally Aluminum alloy and stainless steel, but we also can do titanium alloy steel, copper alloy steel special alloy steel and non-metal material.

Q4: What is the minimum size tolerance you can do?

A4: The minimum size tolerance we can do is 0.001mm.

Q5: What is the biggest range you can do?

A5: The biggest range we can do is 1500mm.

Q6: Can you do precise and complicated CNC parts?

A6: Yes, we can do precise and complicated CNC parts by our 5/4/3 axis CNC machines

Q7: Can you accept sample order?

A7: Yes, we can do sample order per your requirement.

Q8:Can you accept custom packing?

A8: Yes, we can do custom packing as your requirement. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifelong After-Sales Service |

|---|---|

| Application: | Cow |

| Power Source: | Electric |

| Heating and Ventilation Equipment Type: | Hot Blast Stove |

| Epidemic Prevention Equipment: | Aerosol Immune Machine |

| Certification: | CE |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

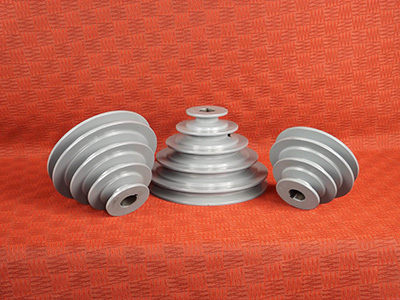

How are step pulleys customized for specific machinery and equipment?

Step pulleys can be customized to meet the specific requirements of machinery and equipment. Here’s how they are customized:

1. Diameter and Step Configuration:

The diameter and step configuration of a step pulley can be customized to match the desired speed range and speed increments of the machinery. The pulley can be designed with the appropriate number of steps and carefully spaced to achieve the desired speed ratios. This customization ensures that the pulley provides the necessary speed options for the specific application.

2. Material Selection:

Step pulleys can be customized by selecting the appropriate materials based on the machinery’s operating conditions and requirements. Different materials, such as cast iron, steel, or aluminum, offer varying levels of strength, durability, and resistance to wear and corrosion. The choice of material depends on factors such as load capacity, environmental conditions, and the specific application.

3. Belt or Cable Compatibility:

Customization of step pulleys includes ensuring compatibility with the type of belt or cable used for power transmission. The pulley’s steps must be designed to engage effectively with the specific belt or cable type. The shape, profile, and dimensions of the steps are customized to ensure proper belt or cable engagement, minimizing slippage and optimizing power transmission efficiency.

4. Mounting Configuration:

Step pulleys can be customized to match the mounting configuration of the machinery or equipment. This includes considerations such as the pulley’s shaft diameter, keyway size, and overall dimensions. Customizing the mounting configuration ensures proper alignment and secure installation of the pulley within the machinery.

5. Load Capacity:

Customization of step pulleys takes into account the load capacity requirements of the machinery. The pulley’s design and construction are customized to handle the anticipated loads without compromising performance or risking premature failure. This may involve reinforcing the pulley structure or selecting a larger size to accommodate higher loads.

6. Special Features:

In some cases, step pulleys may be customized with special features to cater to specific machinery needs. This can include features such as anti-slip coatings, noise reduction enhancements, or additional components for enhanced safety or functionality. Customization allows the step pulleys to integrate seamlessly within the machinery and optimize its performance.

Customization of step pulleys is typically carried out by manufacturers or specialists who take into account the machinery’s specifications, operating conditions, and performance requirements. By tailoring the design and characteristics of the step pulleys, they can be optimized for reliable and efficient operation within the specific machinery or equipment.

How do you select the right step pulley configuration for a specific task?

Selecting the right step pulley configuration for a specific task involves considering several factors to ensure optimal performance. Here’s a step-by-step guide to help you make the right choice:

1. Identify the Speed Range:

Determine the required speed range for the task at hand. Consider the materials being worked on, the cutting tools or processes involved, and any specific speed requirements for achieving the desired results. This will help you understand the range of speeds needed from the step pulley.

2. Assess the Available Speed Options:

Examine the available step options on the pulley system. Count the number of steps and note their respective diameters. Each step corresponds to a specific speed ratio, allowing you to achieve different speed settings. Evaluate whether the available speed options cover the required range for your task.

3. Consider Speed Increments:

Take into account the speed increments or intervals between each step on the pulley system. Some step pulleys offer finer speed adjustments with smaller increments, while others may have larger jumps between steps. Determine if the available increments align with the level of speed control needed for your task. Smaller increments provide more precise speed adjustments.

4. Evaluate Power Transmission Requirements:

Consider the power transmission requirements of your task. Assess the torque and power demands of the machinery or equipment involved. Ensure that the step pulley configuration you choose can handle the required power transmission without overloading or straining the system.

5. Assess Space and Compatibility:

Evaluate the available space and compatibility with your machinery or equipment. Ensure that the step pulley configuration can be properly installed and integrated into the existing system. Consider factors such as pulley size, shaft diameter, and belt compatibility.

6. Consult Manufacturer’s Guidelines:

Refer to the manufacturer’s guidelines, specifications, and recommendations for the machinery or equipment you are working with. The manufacturer may provide specific guidelines on selecting the appropriate step pulley configuration for optimal performance and compatibility.

7. Seek Expert Advice:

If you are unsure about the right step pulley configuration for your specific task, it is recommended to consult with experts or professionals in the field. They can provide valuable insights and guidance based on their experience and expertise.

By following these steps and considering the relevant factors, you can select the right step pulley configuration that aligns with the speed requirements, power transmission needs, and compatibility of your specific task.

In which industries and applications are step pulleys commonly used?

Step pulleys find widespread use in various industries and applications where adjustable speed control is required. Here are some industries and applications where step pulleys are commonly used:

1. Machine Tools:

Step pulleys are extensively used in machine tools such as drill presses, milling machines, and lathes. They allow operators to adjust the rotational speed of cutting tools, enabling precise machining operations.

2. HVAC Systems:

Heating, ventilation, and air conditioning (HVAC) systems often utilize step pulleys in blower motors and fans. These pulleys enable adjusting the speed of the fan to control airflow and temperature regulation.

3. Automotive Industry:

Step pulleys are employed in various automotive applications. They can be found in engine accessories like alternators and power steering systems, where they allow for adjustable speed control.

4. Industrial Machinery:

Step pulleys are used in a wide range of industrial machinery, including conveyors, packaging machines, textile machines, and printing presses. They provide speed variation for different production requirements.

5. Exercise Equipment:

Step pulleys are utilized in exercise equipment like treadmills, stationary bikes, and elliptical machines. They allow users to adjust the difficulty level and intensity of their workouts by changing the speed or resistance.

6. Garage Door Openers:

Step pulleys are commonly found in garage door openers. They enable smooth and controlled opening and closing of garage doors by adjusting the speed and torque applied to the door mechanism.

7. Textile Industry:

In textile manufacturing, step pulleys are used in textile machines such as spinning frames and weaving looms. They provide speed control for various stages of the textile production process.

8. Woodworking Machinery:

Step pulleys are utilized in woodworking machinery, including table saws, band saws, and sanding machines. They enable operators to adjust the speed of cutting or sanding tools for different types of wood and desired finishes.

These are just a few examples, and step pulleys can be found in numerous other industries and applications where adjustable speed control is essential.

editor by CX

2024-05-16