Product Description

Factory Professional Customized OEM CNC Machining Process Aluminum Pulley Precision Powder Coated Black Aluminum Pulley

Basic Information :

| Tolerance | 0.02~0.1mm. |

| Materials | Low, middle,high carbon steel / spring steel / Stainless steel 201, 301, 304, 316 / Aluminum / Brass / Bronze / Copper / Titanium / Plastic (PP, Nylon, PVC, APET) Brass or ABS,POM Ect And Customized raw material. |

| Surface Finish | Heat treatment / Polishing,Electronic Polishing / (Zinc, nickel, chrome, tin, brass, glod, silver, titanium) Plating / Electrophoresis / Black Oxide / Hot-dip galvanizing / Powder Coating / Paint Coating / Blasting / Shot Blasting / Bead Basting / Anodizing / Phosphating / PAD Printing / Laser etching / Dacromet Coating / Enamel. |

| Payment terms | Trade Assurance TT,paypal,Western Union,alipay,L/C. |

| Packing Detail |

Inner Packing: PE bag / EPE Foam Packing / Anti-Rust Paper Packing / Blister / SMT / Vacuum Packing / Plastic Box Packing / Color Box Packing. Outter Packing: Stretch Film Packing / Carton / Pallet / Wood Case. |

Our Advantage

-

Provide OEM/ODM service and assembling service, since 2000.

- One-stop purchasing service :Stamping part, CNC lathe part, CNC milling part, Springs, Shafts, fastener etc.

- The 2ndtier supplier of , factory audits passed.

- Product certification: RoHS, HE, vailable.

- Management certification: ISO/9001: 2015 and IATF16949 Passed.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory |

|---|---|

| Standard: | GB |

| Surface Treatment: | Anodizing |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | Order Sample Customized services

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What is the significance of proper alignment and tensioning in step pulley systems?

Proper alignment and tensioning are crucial for the optimal performance and longevity of step pulley systems. Here’s why they are significant:

1. Efficient Power Transmission:

Proper alignment ensures that the step pulleys and the belts or cables are correctly positioned relative to each other. This alignment allows for efficient power transmission from the driving pulley to the driven pulley. When the pulleys are aligned, there is minimal slippage or energy loss, resulting in efficient transfer of power and improved overall system performance.

2. Minimized Wear and Damage:

Correct tensioning of the belts or cables is essential to prevent excessive wear and damage. When the tension is too loose, the belts or cables may slip, causing accelerated wear and heat generation. On the other hand, if the tension is too tight, it can lead to increased stress on the pulleys, bearings, and belts or cables, potentially causing premature failure. Proper tensioning helps maintain the optimal balance, reducing wear and extending the service life of the components.

3. Reduced Vibration and Noise:

Misalignment or improper tensioning can result in vibration and noise in the step pulley system. Vibrations can affect the overall stability of the machinery and contribute to increased wear and fatigue on the pulleys and other components. Proper alignment and tensioning help minimize vibrations, resulting in smoother and quieter operation, which is desirable for both operator comfort and the longevity of the system.

4. Prevented Belt or Cable Slippage:

Proper alignment and tensioning significantly reduce the risk of belt or cable slippage. Slippage can occur when the belts or cables lose traction with the pulleys, leading to a loss of power transmission and compromised performance. By ensuring proper alignment and tension, the risk of slippage is minimized, ensuring reliable and consistent power transfer.

5. Extended Component Life:

When step pulleys, belts or cables, and other system components are properly aligned and tensioned, they experience less stress and wear. This contributes to extended component life and reduces the frequency of replacements or repairs. Proper maintenance of alignment and tensioning helps protect the integrity of the system, minimizing the risk of sudden failures and downtime.

6. Improved Efficiency and Productivity:

By maintaining proper alignment and tensioning, step pulley systems operate at their optimum efficiency. The ability to transfer power smoothly and reliably enhances the productivity of the machinery or equipment. It allows for accurate speed control and consistent performance, leading to improved production output and quality.

In summary, proper alignment and tensioning are of utmost importance in step pulley systems. They ensure efficient power transmission, minimize wear and damage, reduce vibration and noise, prevent slippage, extend component life, and improve overall system efficiency and productivity.

What safety considerations should be kept in mind when working with step pulleys?

Working with step pulleys involves certain safety considerations to prevent accidents and ensure the well-being of individuals involved. Here are some important safety guidelines to keep in mind:

1. Read and Follow Manufacturer’s Instructions:

Before operating any machinery or equipment with step pulleys, carefully read and understand the manufacturer’s instructions, warnings, and safety guidelines. Follow them strictly to ensure safe usage.

2. Wear Personal Protective Equipment (PPE):

Always wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection, when working with step pulleys. PPE helps protect against potential hazards, including flying debris, entanglement, and noise.

3. Machine Guarding:

Ensure that all necessary machine guards and safety shields are in place and properly functioning. Machine guards help prevent accidental contact with moving parts, including step pulleys, reducing the risk of injury.

4. Lockout/Tagout Procedures:

Follow lockout/tagout procedures when performing maintenance or repair tasks on machinery with step pulleys. Lockout/tagout involves isolating the equipment from its power source and securing it to prevent accidental startup during maintenance activities.

5. Proper Training and Supervision:

Ensure that operators and maintenance personnel receive proper training on the safe operation and maintenance of machinery with step pulleys. Supervise their work initially until they have gained sufficient experience and competence.

6. Avoid Loose Clothing and Jewelry:

Avoid wearing loose clothing, jewelry, or anything that could get entangled in the moving parts of the machinery, including step pulleys. Loose items can pose a serious risk of entanglement and injury.

7. Use Proper Tools and Equipment:

Use the appropriate tools and equipment when working with step pulleys. Using improper tools or makeshift solutions can lead to accidents or damage to the equipment.

8. Regular Maintenance and Inspection:

Perform regular maintenance and inspection of the machinery and step pulley system. Check for any signs of wear, damage, or misalignment. Address any issues promptly to ensure safe and efficient operation.

9. Report and Address Safety Concerns:

If you notice any safety concerns or potential hazards related to the step pulley system, promptly report them to the appropriate personnel. Take necessary actions to address the concerns and ensure a safe working environment.

10. Follow Safe Work Practices:

Adhere to safe work practices, such as keeping the work area clean and organized, maintaining proper lighting, and avoiding distractions. These practices contribute to a safer work environment when working with step pulleys.

By following these safety considerations and guidelines, you can minimize the risks associated with working with step pulleys and create a safer working environment for yourself and others.

Can you explain the key components and design features of a step pulley?

A step pulley consists of several key components and design features that enable its functionality. Here are the main components and design features:

1. Pulley Wheel:

The pulley wheel is the main component of the step pulley. It is typically a cylindrical or disk-shaped wheel with multiple grooved steps or levels on its circumference. Each step corresponds to a specific diameter.

2. Steps:

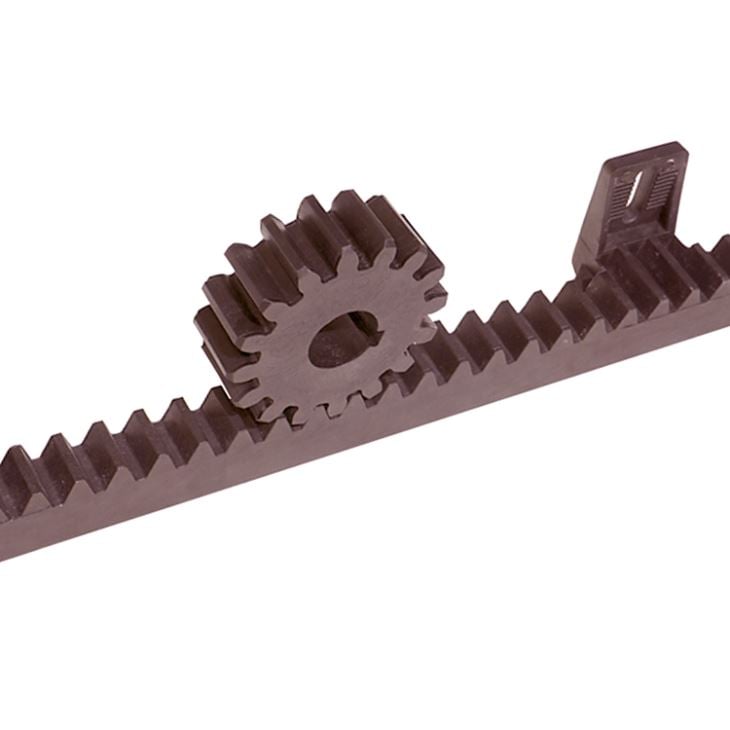

The steps on a step pulley are the different levels or grooves machined into the pulley wheel. These steps have varying diameters, which determine the speed ratio when the belt or chain is moved between them. The operator can manually adjust the belt or chain position to different steps to achieve the desired speed.

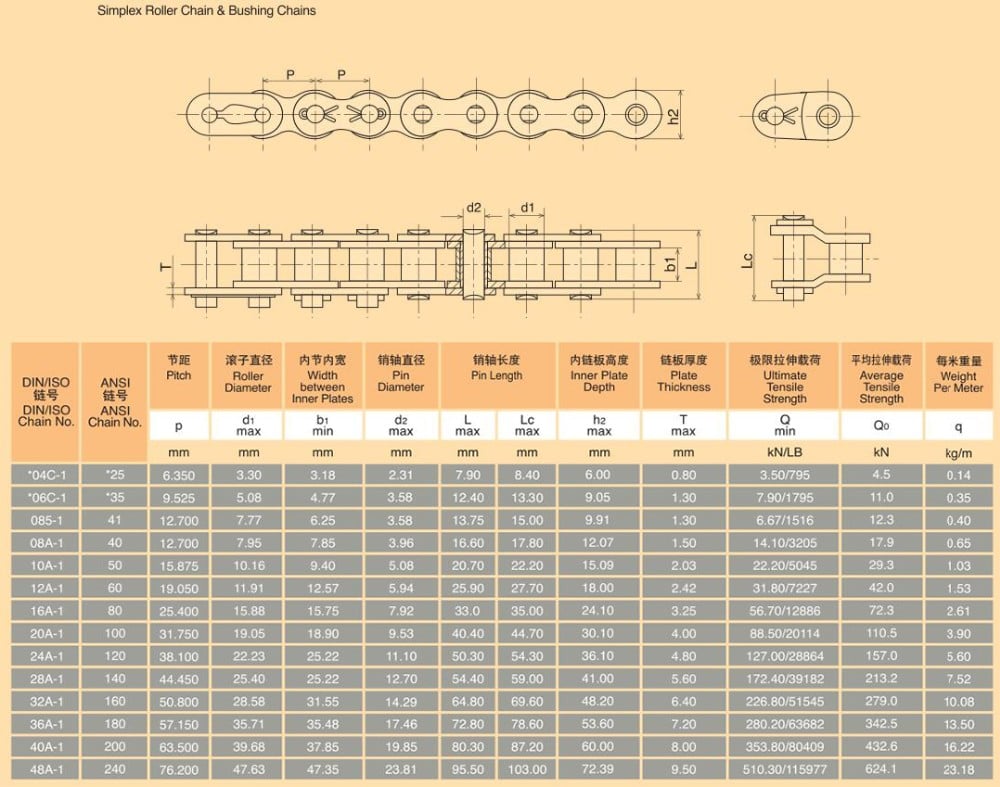

3. Belt or Chain:

A belt or chain is used to transmit power from the driving pulley to the driven pulley. It wraps around the steps of the pulley and engages with the corresponding grooves. The belt or chain is moved from one step to another to change the effective diameter and adjust the speed ratio.

4. Manual Adjustment Mechanism:

Step pulleys are designed to allow manual adjustment of the belt or chain position. This adjustment is typically achieved by sliding or shifting the belt or chain between steps. The pulley may have a mechanism such as a lever, handle, or knob to facilitate easy adjustment.

5. Support and Mounting:

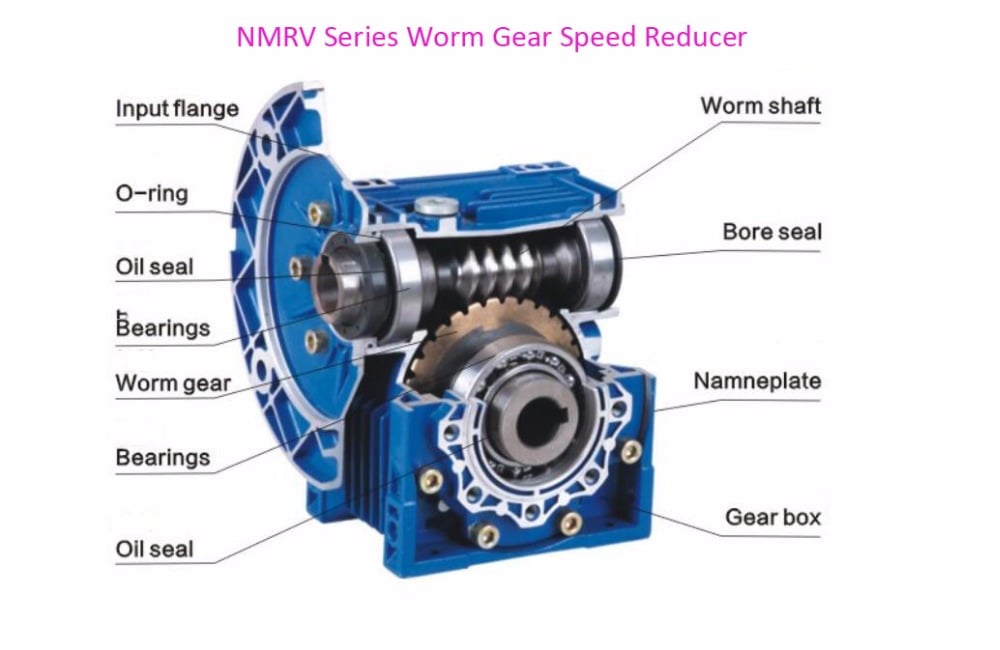

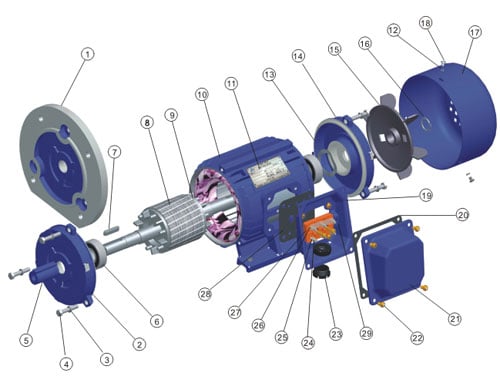

Step pulleys are mounted on shafts that are supported by bearings or bushings. The pulley shaft is connected to the driving source, such as an electric motor or an engine, and the driven component through a power transmission system.

6. Material and Construction:

Step pulleys are usually made of durable materials such as cast iron, steel, or aluminum. The pulley is precision-machined to ensure accurate step dimensions and smooth operation.

7. Size and Configuration:

The size and configuration of step pulleys can vary depending on the specific application and requirements. They can range from small pulleys used in handheld tools to larger pulleys used in industrial machinery.

8. Safety Features:

Some step pulleys may include safety features such as guards or covers to prevent accidental contact with moving parts and reduce the risk of injury.

These key components and design features work together to enable the step pulley to provide variable speed options and adjustability in mechanical systems.

editor by CX

2024-05-13